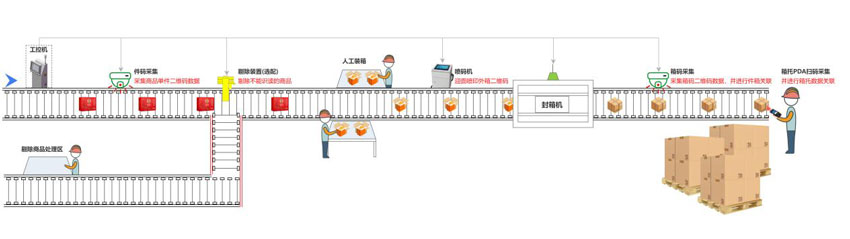

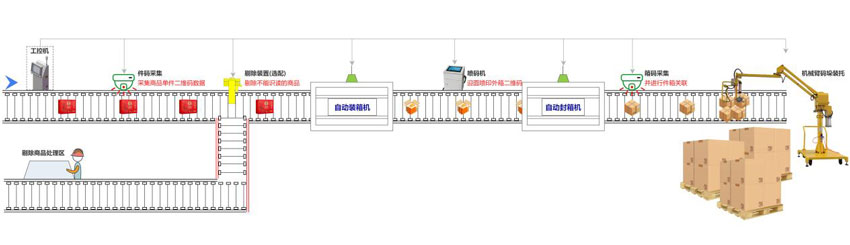

In the production line renovation, traceability code collection employs a dual mode of automation (industrial control computers, RFID, PDAs) and manual operation to ensure data accuracy and fault tolerance. The coding equipment is categorized by process into the packaging stage (TTO, laser marking) and online coding (jet printer, DPM). High-speed and precise coding is achieved through PLC or sensor linkage. The system integrates middleware and dual databases, supporting real-time verification and anti-duplicate features, with provisions for blockchain and AI maintenance expansion. This solution can boost collection efficiency to 99.9%, implemented in three phases, balancing compliance and cost optimization.